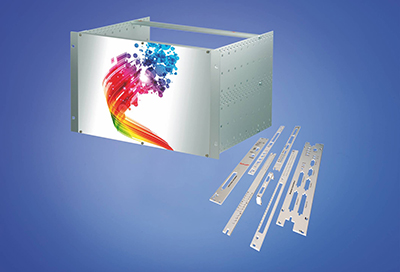

Front Panel Treatment - Processing, Painting, Engraving, Anodizing, Printing

We can customize your front panels in various ways to suit your needs, such as mechanical processing, painting, engraving, anodizing, and printing (including sub-anodic printing).

For more sophisticated design preferences, we can apply image, graphic, and text information to the front panel we have already preprocessed using digital printing - another step towards personalizing your products.

With our online configurator, you can customize your front panel according to your preferences. Challenging design requirements like image, graphics and text information will be transferred via digital printing to the pre-finished front panel - an additional step towards customizing your products.

You prefer to receive advice over the phone?

Call us at +49 30 700 1154-0

UV Digital Printing

With UV digital printing from nVent SCHROFF, the possibilities for design options for front panels and other components are significantly expanded. At the same time, a positive contribution is made to the environment.

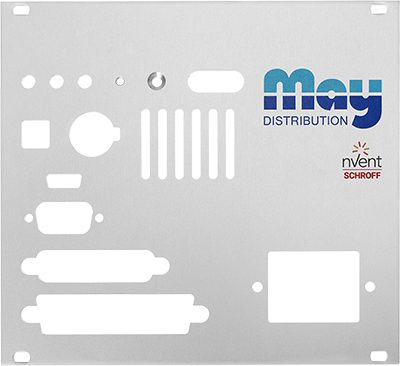

UV Digital Printing on Metal

(FPL1)

Printed with various font sizes, line thicknesses, and symbols to demonstrate the vibrant, opaque colors, alongside the high resolution of the new printing technology.

UV Digital Printing on Fine Structure Paint (FPL2)

Printing identical to FPL1, the difference to FPL1 is that this front panel was previously painted with RAL 9016 (Traffic White) fine structure paint to demonstrate how a different background can influence the appearance of the print.

UV Digital Printing on Underprint

(FPL3)

This front panel is fully underprinted in white with a very colorful design to demonstrate the vibrant colors and printable white. Compared with FPL2, here you can see the difference between printable white and a painted RAL white shade.

A sample speaks louder than a thousand words

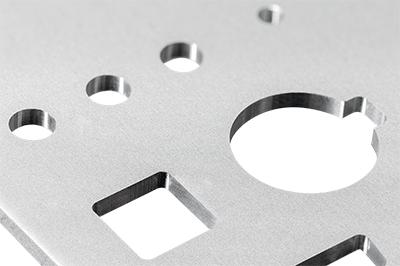

We want to convince you! That's why we offer you the above-described UV digital printed front panels as samples (FPL 1, FPL 2, FPL 3) to demonstrate the possibilities and different effects: 3U 10HP aluminum front panels, anodized front, conductive back.

Contact us at +49 30 700 1154-0

The Advantages at a Glance

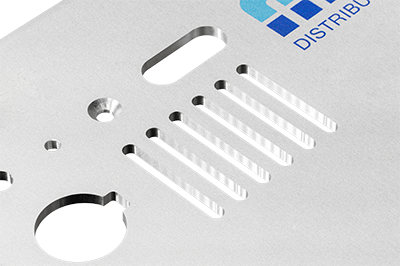

- Vibrant, opaque colors create an impressive, high-resolution print image and allow for full-surface printing of components.

- With an optional white underprint, the colors appear even more vibrant, and the influence of the printing material (e.g., aluminum front panel) is minimized.

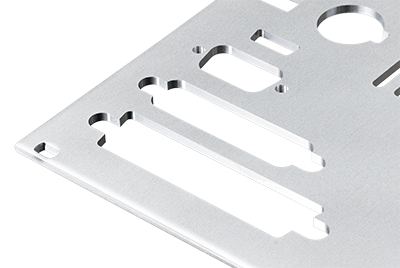

- In addition to metallic surfaces, plastics, painted, and powder-coated surfaces can now be digitally printed.

- The heat treatment of printed products is no longer necessary, as the curing of the printing inks is achieved through UV light, making the entire process more environmentally friendly.

- Greenguard Gold (UL 2818) certified inks meet strict standards for low emissions of volatile organic compounds (VOC) and ensure that printed products can be used in sensitive environments (e.g., medical facilities) without compromising indoor air quality.

Validation Process

To ensure that the new printing process meets industry-specific quality requirements, as well as the quality requirements of nVent SCHROFF, it underwent rigoros testing. Amon others, the following tests were conducted with positive results:

- Adhesion of the printing ink.

- Resistance to mechanical stress (scratches, machining, and press-fitting processes).

- Chemical resistance (sweat, hand creams, various solvents).

- Resistance to specific environmental conditions (salt spray, climate testing).

Our Service for You

During the order processing, we select the most suitable printing technology for you, taking into account individual customer requirements as well as technical and economic aspects.

We aim to convince you! Therefore, we offer printed front panel samples to demontrate the possibilities and different effets: 3HU 10HP aluminium front panels with anodized front and conductive back, UV digitally printed using the above mentioned methods.

Feel free to contact us at +49 30 700 1154-0